Picture this: a hurricane knocks out your power, and within hours, your refrigerator's contents begin a silent, costly descent into spoilage. Or imagine plugging a new energy-efficient fridge into an outdated circuit, only to plunge your kitchen into darkness. Behind these everyday scenarios lies a critical but overlooked question—how many amps does your refrigerator truly demand? Understanding this electrical heartbeat isn't just about preventing tripped breakers; it's the key to food security, energy efficiency, and resilience when disasters strike.

Refrigerators are deceptive power consumers. While they hum quietly in the background, their electrical needs fluctuate dramatically between dormant periods and intense cooling cycles. Misjudging their amperage can lead to melted wires, failed generators, or thousands in spoiled groceries. This article demystifies the complex interplay of volts, watts, and amps that keeps your food safe—and reveals how modern power solutions are rewriting the rules of refrigeration resilience.

Decoding Refrigerator Electrical Fundamentals

At its core, a refrigerator's power consumption revolves around three intertwined elements: voltage (V), amperage (A), and wattage (W). Most household refrigerators operate on a standard 120-volt circuit in North America, following the fundamental equation: Amps = Watts ÷ Volts. A typical modern fridge might consume 600-800 watts during active cooling cycles, translating to 5-6.6 amps at 120V. However, this represents only part of the story. The compressor—the refrigerator's power-hungry heart—requires significantly more energy during startup than during sustained operation. This startup surge, often called "locked rotor amps," can spike to 3-7 times the running amperage for 1-3 seconds. Older refrigerators are particularly demanding; a 1990s side-by-side might draw 8-9 running amps with surges exceeding 20 amps. This surge phenomenon explains why refrigerators frequently trip undersized circuits or generators incapable of handling brief but intense power bursts. Understanding these fundamentals is essential not just for daily operation, but for selecting backup power systems that can manage these aggressive electrical demands during outages.

Modern inverter refrigerators have improved efficiency but introduced new complexities. By using variable-speed compressors, they adjust cooling output gradually rather than cycling fully on/off. This eliminates dramatic startup surges but creates prolonged higher-amperage periods. For example, after door opening, an inverter fridge might draw a steady 7 amps for 20 minutes instead of spiking to 15 amps for 3 seconds. While gentler on circuits, this requires sustained power delivery rather than brief surge capacity. Additionally, features like ice makers and digital displays add constant "phantom loads" of 0.5-1 amp even during idle periods. These nuances underscore why amp calculations must consider both peak demands and continuous draw patterns. Homeowners should also account for voltage drops in older wiring—a fridge requiring 6 amps at 120V might draw 8 amps if voltage sags to 90V at the outlet due to undersized wires, potentially causing dangerous overheating.

Calculating Your Refrigerator's True Amperage Needs

Accurately determining your refrigerator's amperage requires moving beyond manufacturer averages to real-world measurements. Begin by locating the UL-rated nameplate—usually inside the door frame or on the back—which lists running amps (RLA) and occasionally startup surge (LRA). If LRA isn't provided, multiply RLA by 3 as a safety buffer. For example, a fridge rated at 6 RLA likely needs 18 LRA momentarily. However, nameplate values reflect laboratory conditions. Actual consumption varies with usage patterns, ambient temperature, and maintenance. A refrigerator in a 90°F garage may draw 40% more amps than one in a 70°F kitchen. Similarly, dirty condenser coils force compressors to work harder, increasing amperage by up to 30%. To capture these variables, use a clamp meter around the refrigerator's dedicated circuit wire. Measure during three scenarios: idle operation (compressor off), active cooling cycles, and immediately after door closure when demand peaks. Record the highest observed amperage over 24 hours to account for defrost cycles, which add 1-3 amps for 20-40 minutes.

For backup power planning, these measurements inform critical decisions. A generator must exceed both running amps and startup surges simultaneously. If your fridge requires 6A running but surges to 18A, a 15A generator will fail despite appearing sufficient for continuous load. Furthermore, refrigerators share circuits with other kitchen appliances. If your fridge draws 7A but shares a 15A circuit with a 5A lighting load, cumulative demand risks tripping breakers. Always calculate total circuit load: sum the running amps of all devices on the circuit, then add the largest single appliance's startup surge. For safety, continuous loads shouldn't exceed 80% of circuit capacity—so a 15A circuit should max at 12A continuous. When upgrading appliances, consider both efficiency labels (ENERGY STAR units often use 4-5 running amps) and physical dimensions. A larger French-door fridge may consume fewer amps than a smaller frost-free model due to advanced insulation and compressors, defying conventional assumptions about size and power consumption.

Backup Power Solutions for Refrigeration Emergencies

When grid power fails, preserving refrigeration becomes a race against time. Traditional gasoline generators often stumble with refrigerator startups due to insufficient surge capacity. A 2,000-watt generator might handle 16.6 running amps at 120V but fail to deliver the 40-50 amps briefly required during compressor startup. Solar generators like OUPES' Mega series overcome this limitation with advanced lithium batteries and pure sine wave inverters specifically engineered for surge-intensive appliances. Their "SurgeShield" technology delivers up to 12,000 watts momentarily—enough to start even demanding refrigerators—before settling to efficient running wattage. Unlike fuel-dependent generators, these systems operate silently indoors without toxic emissions, making them safe for apartment balconies or enclosed patios during storms. Runtime calculations must consider both active and idle periods; while a fridge compressor runs 30-50% of the time, battery systems must accommodate 24/7 phantom loads and periodic defrost cycles. For example, a 120Ah solar generator can typically sustain a modern fridge for 18-36 hours depending on ambient temperatures and door openings.

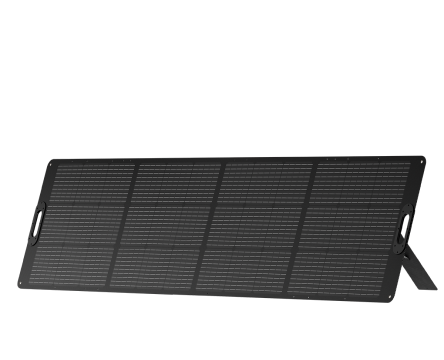

Integrating solar panels transforms these systems from short-term backups to sustainable power hubs. During extended outages, 400W solar panels can fully recharge a power station in 4-6 hours of sunlight, creating indefinite refrigeration support. Critical to success is matching panel wattage to both refrigerator consumption and battery capacity. A fridge averaging 1.2kWh daily requires at least 300W of solar input under optimal conditions—more if cloudy. Smart management features like OUPES' app monitor real-time amp draw, alerting users to abnormal consumption that might indicate failing compressors or door seal issues. For whole-home resilience, modular systems allow linking multiple batteries to power refrigerators alongside medical devices or communication equipment. This scalability proves invaluable during multi-day blackouts, where gasoline scarcity renders conventional generators useless. By pairing efficient refrigeration with solar regeneration, households create self-sustaining food preservation ecosystems untethered from fragile grids.

Optimizing Efficiency to Reduce Amperage Demands

Strategic usage adjustments can significantly reduce a refrigerator's amp draw, easing strain on circuits and backup systems. Begin by setting temperatures wisely: the FDA recommends 37°F for fridges and 0°F for freezers. Each 5°F decrease increases energy consumption by 15-25%, directly raising amperage. Next, manage door discipline—every 10-second opening requires 45 minutes of compressor runtime to restore temperatures. Installing interior LED lights (drawing just 0.02A vs. 0.5A for incandescents) reduces heat buildup during access. Physical maintenance dramatically impacts efficiency: vacuuming condenser coils quarterly prevents dust "insulation" that forces compressors to work harder, potentially lowering amperage by 20%. Similarly, checking door seals with the dollar bill test ensures cold air retention. For older units, upgrading to a modern inverter-driven compressor can halve amp requirements while providing more stable temperatures.

Environmental modifications further enhance performance. Positioning refrigerators away from heat sources like ovens or direct sunlight prevents ambient heat gain. In hot climates, adding ventilation fans behind the unit improves heat dissipation from condenser coils, reducing runtime. During outages, proactive measures conserve backup power: pre-chilling spaces to 35°F before storms creates thermal mass that slows warming. Freezing water jugs provides emergency cooling while stabilizing humidity. Grouping items reduces air circulation loss during brief openings. For solar generator users, these practices extend runtime exponentially—a 10% reduction in amp draw might yield 30% longer operation by minimizing compressor cycles. Ultimately, understanding that a refrigerator's electrical needs are dynamic—not fixed—empowers homeowners to balance preservation needs with energy constraints, especially during crises when every amp-hour counts.

Understanding your refrigerator's amperage transcends electrical theory—it's fundamental to food security, safety, and efficient home management. From calculating startup surges that dictate generator sizing to implementing daily efficiency habits that reduce strain on aging circuits, this knowledge forms the bedrock of appliance longevity and disaster preparedness. Modern refrigerators, while increasingly efficient, still present complex electrical profiles that demand careful consideration beyond nameplate ratings.

As climate disruptions increase outage frequency, pairing amp awareness with resilient power solutions transforms vulnerability into confidence. Solar generators exemplify this evolution, offering surge-capable, emissions-free refrigeration support that traditional generators cannot match. By marrying technical understanding with proactive optimization, households ensure their refrigerators serve not just as food preservers, but as reliable pillars of everyday resilience—powered by photons when the grid falls silent.