As Captain Elara Rodriguez battled 15-foot swells off Cape Horn, her vessel's navigation systems flickered ominously—until marine solar cells sewn into the sails converted Antarctic glare into life-saving power. This real-world scenario reveals why marine solar technology has revolutionized modern seafaring. Unlike terrestrial panels, marine solar cells confront unique challenges: corrosive salt spray, constant motion, and space constraints that demand ingenious engineering solutions.

From rigid deck-mounted panels to flexible cells integrated into bimini tops, marine solar arrays transform seawater reflections into reliable electricity for critical systems. Understanding their physical dimensions and charging mechanics isn't just technical knowledge—it's the difference between being stranded at sea and maintaining communication, refrigeration, and navigation during extended voyages. Let's navigate the specifics of these oceanic power generators.

Physical Dimensions and Space Optimization Strategies

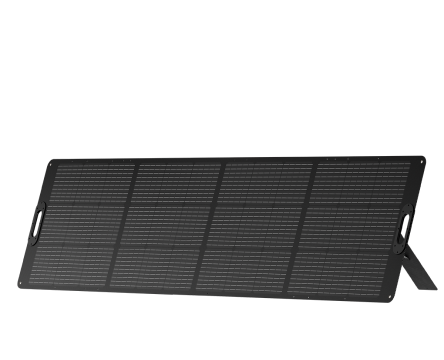

Marine solar cells span a remarkable size spectrum, from compact 10-watt units to expansive 400-watt systems, with dimensions directly correlating to power output. Rigid monocrystalline panels dominate deck installations, typically measuring 65x39 inches for 300W models—comparable to a large suitcase but only 1.5 inches thick. Flexible thin-film alternatives offer radical space savings at 0.1-inch thickness, conforming to curved surfaces like cabin tops or radar arches. Sail-integrated photovoltaic fabrics represent the frontier, with 4x6-foot sections woven directly into mainsails adding 150W without altering vessel aerodynamics. For sailboats, the golden ratio is 1:10—1 watt of solar per 10 pounds of boat displacement—meaning a 10,000-pound cruiser ideally needs 1,000W. Power catamarans double this requirement for air conditioning loads. Clever mounting solutions maximize real estate: arch systems above cockpits hold 3-4 panels without sacrificing deck space, while swim platform brackets deploy panels horizontally when anchored. Retractable systems slide panels from lockers during daylight, then stow for night passages. The emerging trend? Modular micro-panels like OUPES' 100W marine tiles (19x14 inches each) that assemble puzzle-like across irregular surfaces, generating 400W from 16 square feet—proving that on cramped vessels, solar efficiency trumps raw size every time.

Space constraints demand innovative layering. Modern installations often combine panel types: rigid main arrays on hardtops supplemented by flexible strips along lifelines. Power density calculations guide placement—monocrystalline yields 15-22W per square foot versus thin-film's 8-12W. For liveaboards, panels double as shade providers; bimini-top installations shield cockpits while generating 300-500W. On sailing yachts, the boom becomes prime real estate with track-mounted panels that rotate with wind direction. When evaluating systems, consider not just panel dimensions but required clearance: rigid panels need 3-inch airflow gaps beneath to prevent heat buildup (which reduces efficiency 0.5% per °F above 77°F). The ultimate metric? Watts per cubic meter of occupied space—where well-designed marine solar should deliver 80-120W/m³ without compromising functionality.

Saltwater Charging Dynamics and Energy Harvesting

Marine charging systems combat unique environmental challenges through specialized engineering. Unlike terrestrial setups, marine solar controllers must compensate for vessel motion-induced shading and reflective glare from water surfaces. Advanced Maximum Power Point Tracking (MPPT) controllers like those in OUPES marine kits constantly adjust voltage/amperage ratios to capture "glinting energy"—the intensified photons bouncing off waves that can boost output 20% during midday. Charging occurs in three phases: bulk (80% capacity at maximum available current), absorption (voltage-limited topping), and float (maintenance mode). Saltwater conductivity demands galvanic isolation; marine-grade charge controllers use opto-isolated circuits to prevent electrolytic corrosion between dissimilar metals. For lithium iron phosphate (LiFePO4) batteries—now standard in marine applications—controllers enforce strict voltage ceilings (14.6V max for 12V systems) and temperature-compensated charging, reducing absorption voltage 0.03V per °F above 85°F to prevent plating.

Real-world charging varies dramatically with conditions. Under tropical sun, a 300W array can produce 1.5kWh daily—enough to power refrigeration and navigation. Cloudy coastal cruising may yield just 0.3kWh, emphasizing the need for hybrid systems. Smart controllers integrate with alternators and wind generators, prioritizing solar while blending sources. During passage-making, dynamic charging profiles adjust for heel angles: when a sailboat tilts 30 degrees, panels automatically increase voltage 15% to compensate for reduced surface exposure. The most advanced systems even harness vessel movement; piezoelectric strips in deck-mounted panels convert wave-impact vibrations into supplemental power. Critical to success is oversizing panels by 30% versus calculated needs—salt crust and humidity inevitably degrade performance. Monitoring via Bluetooth apps shows real-time harvest data, with alerts for shadowing from sails or unexpected resistance increases indicating corrosion in terminals.

Corrosion Resistance and Seaworthy Durability

Marine solar components employ multi-layered defense systems against saltwater degradation. Anodized aluminum frames undergo 5,000-hour salt spray testing (ASTM B117), with stainless steel hardware rated 316L—containing molybdenum for chloride resistance. Junction boxes achieve IP68 certification through dual silicone gaskets and potted electronics, surviving submersion at 10-foot depths. The true innovation lies in cell protection: marine panels sandwich photovoltaic layers between ethylene tetrafluoroethylene (ETFE) polymer sheets instead of glass, providing shatter resistance while blocking UV degradation. ETFE's non-stick surface enables "rain cleaning"—where water beads carry salt crystals away. For flexible panels, manufacturers embed corrosion inhibitors like zinc nanoparticles within the polymer matrix, creating sacrificial anodes at microscopic levels.

Electrical components face even harsher challenges. Marine-rated MC4 connectors feature gold-plated contacts submerged in dielectric grease, with triple-sealed collars preventing capillary action. Cabling uses tinned copper strands with abrasion-resistant jackets, often colored white to reflect heat. Mounting systems avoid direct metal contact; composite shims isolate aluminum frames from stainless brackets to prevent galvanic corrosion. Maintenance protocols include quarterly rinsing with deionized water (never tap—minerals create conductive paths) and annual application of anti-corrosive sprays to terminals. The benchmark? Quality marine solar should withstand Category 4 hurricane conditions—150mph winds and horizontal rain—without failure. Accelerated aging tests simulate 20-year lifespans through 10,000 thermal cycles (-4°F to 185°F) and constant vibration at 30Hz. This extreme durability justifies the premium over terrestrial panels; where standard panels last 5-7 years at sea, marine-specific installations deliver 12-15 years of reliable service.

Installation Techniques for Dynamic Marine Environments

Marine solar installation balances structural integrity with energy optimization. Hardtop mounts require strategic reinforcement; core sampling identifies solid fiberglass sections before bonding 4mm aluminum backing plates with epoxy. Through-bolt installations (never screws) distribute load across 16 square inches per bracket. For curved surfaces like cabin tops, flexible panels adhere via UV-stable 3M VHB tape with secondary mechanical fasteners at corners. The critical factor? Avoiding "hard points"—rigid mounts that transfer hull flexing stress to panels. Modern solutions use articulated mounts with ball joints allowing 15 degrees of movement in all directions. Wiring demands equal attention; conduit runs follow the "drip loop" principle—creating U-shaped dips before connections to prevent water ingress. All penetrations use Marelon seals with UV-resistant butyl tape backup.

Electrical configuration depends on vessel motion. Series wiring minimizes amperage (reducing fire risk) but suffers when partial shading occurs—common with mast shadows. Parallel setups maintain output under shading but require thicker gauge wiring. Hybrid "series-parallel" arrays offer the best compromise, with each sub-array operating independently. For sailing yachts, panel positioning considers typical heel angles; starboard-biased installations capture more light in the Northern Hemisphere's prevailing winds. Power management integrates with vessel systems via marine-grade bus bars with active current monitoring. Smart installations include tilt-adjustment systems—manual knobs for seasonal angle changes or automated actuators that track the sun across 180 degrees. Post-installation, thermographic scans identify "hot spots" indicating poor connections, while insulation resistance tests verify >100 megohm integrity. The ultimate validation? Open-ocean performance logging that confirms consistent power delivery even in 45-degree rolls and green-water deck immersion.

Marine solar cells represent a remarkable fusion of renewable energy and nautical engineering, transforming harsh marine environments into power-generating assets. Their specialized dimensions and charging systems address the unique spatial constraints and corrosive challenges of life at sea, enabling true energy independence far from shore.

As technology advances, the integration of solar power into vessel design grows increasingly seamless—from sail-embedded photovoltaic fibers to AI-optimized charging systems. For modern mariners, understanding these systems isn't just about harnessing the sun; it's about ensuring safety, comfort, and sustainability across every nautical mile of their aquatic journeys.