Table of Contents

Introduction

Solar panels are one of the most reliable and sustainable sources of renewable energy available today. Whether they’re mounted on rooftops or paired with portable power stations for off-grid use, modern solar panels are built to last for decades. But exactly how long do they last, and what factors influence their lifespan? This article explores the science behind solar panel durability, the real-world performance you can expect, and how proper care can help maximize their efficiency and return on investment.

Average Lifespan of Solar Panels

Most high-quality solar panels last between 25 to 30 years before their power output significantly decreases. According to the National Renewable Energy Laboratory (NREL), most solar panels still produce around 80% of their original capacity even after 25 years. That means they can keep generating electricity long after their warranty period, though at reduced efficiency.

Typical Warranty Periods

- Product Warranty: Covers manufacturing defects, usually 10–15 years.

- Performance Warranty: Guarantees energy production, typically 25 years.

However, this doesn’t mean the panels stop working after 25 years. It simply indicates a gradual decline in efficiency. Many solar installations continue to function effectively for 35 years or more, especially when properly maintained.

Understanding Solar Panel Degradation

The degradation rate refers to the gradual loss of a solar panel’s ability to convert sunlight into electricity over time. The average annual degradation rate is around 0.5% per year for modern panels.

Example of Long-Term Efficiency

| Years of Use | Average Efficiency Remaining |

|---|---|

| 10 years | 95% |

| 20 years | 90% |

| 25 years | 87.5% |

| 30 years | 85% |

This steady performance decline is largely due to environmental exposure — UV radiation, temperature fluctuations, and moisture can slowly impact photovoltaic (PV) cells. However, advancements in materials and coatings have significantly reduced degradation in newer models.

Factors That Affect Solar Panel Lifespan

Several environmental and technical factors influence how long your solar panels will last:

1. Material Quality

Panels made from monocrystalline silicon tend to last longer and degrade more slowly than polycrystalline or thin-film alternatives due to their higher purity and structural integrity.

2. Installation Quality

Improper installation can lead to mechanical stress, loose wiring, or water ingress, all of which shorten lifespan. Professional installation ensures proper tilt, ventilation, and structural stability.

3. Environmental Conditions

Panels in harsh climates — with frequent hail, heavy snow, or high humidity — may experience faster wear. In contrast, panels in moderate, sunny environments maintain performance longer.

4. Maintenance Practices

Routine cleaning, inspection, and timely removal of debris help prevent microcracks and shading issues that can reduce efficiency over time.

5. Inverter and Connection Quality

Even if the panels themselves remain efficient, degraded inverters or corroded connectors can limit energy transfer, creating a “bottleneck” that affects system output.

Types of Solar Panels and Their Longevity

Different panel types have different expected lifespans and performance characteristics:

| Type | Average Lifespan | Efficiency Range | Degradation Rate |

|---|---|---|---|

| Monocrystalline | 25–35 years | 18–23% | ~0.3%/year |

| Polycrystalline | 20–30 years | 15–18% | ~0.5%/year |

| Thin-Film (Amorphous) | 10–20 years | 10–13% | ~1%/year |

Monocrystalline panels are more expensive but offer superior efficiency and longevity, making them a popular choice for both home and portable solar power systems.

Maintenance Tips to Extend Lifespan

Even though solar panels are low-maintenance, following these best practices helps extend their useful life:

1. Regular Cleaning

Dust, pollen, and bird droppings can reduce sunlight absorption. Clean panels every 3–6 months using soft brushes and water (avoid harsh detergents).

2. Inspect for Damage

Check for cracks, discoloration, or loose cables. Early detection prevents minor issues from becoming major efficiency losses.

3. Monitor Energy Output

Track daily or monthly power production. Sudden drops in output may indicate shading, wiring issues, or inverter faults.

4. Ensure Proper Ventilation

Overheating accelerates degradation. Leave space between panels and mounting surfaces to allow airflow.

5. Protect from Extreme Weather

In areas prone to hail or hurricanes, install protective barriers or tilt panels to minimize impact damage.

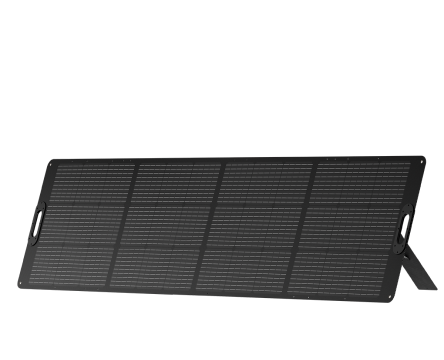

How Portable Solar Panels Differ

Portable solar panels — commonly used with portable power stations or solar generators — are designed for mobility, making them more flexible but slightly less durable than fixed installations. They’re often used for RVs, camping, and backup power.

Average Lifespan of Portable Solar Panels

High-quality portable solar panels typically last 10–15 years, depending on usage frequency and storage conditions. Panels using ETFE coatings and monocrystalline cells offer better resistance to UV damage and wear.

Maintenance for Portable Panels

- Store in a cool, dry place when not in use.

- Clean surfaces gently after each trip.

- Avoid bending or folding panels excessively.

- Use protective cases for transport.

Comparison: Traditional vs. Portable Solar Panels

| Feature | Traditional Solar Panels | Portable Solar Panels |

|---|---|---|

| Average Lifespan | 25–30 years | 10–15 years |

| Installation Type | Fixed (roof or ground) | Foldable, mobile |

| Maintenance | Minimal | Frequent cleaning and storage care |

| Power Output | High (up to 400W+ per panel) | Moderate (100–240W per panel) |

| Use Case | Residential / Commercial | Camping / RV / Backup |

How OUPES Utilizes Long-Lasting Solar Technology

Modern portable energy companies such as OUPES integrate high-efficiency monocrystalline solar panels with ETFE protective layers to ensure durability and performance. These panels maintain strong conversion rates even after years of outdoor exposure. When paired with a reliable OUPES power station, they form a complete solar generator system capable of powering everything from camping gear to home appliances sustainably and quietly.

FAQ

1. How long do solar panels really last?

Most solar panels last 25–30 years, with efficiency slowly decreasing over time. Many continue working well beyond that period at slightly reduced performance.

2. Do solar panels stop working after 25 years?

No. The 25-year mark refers to the warranty period, not the end of functionality. Panels typically produce 80–85% of their original output even after that.

3. How can I tell if my solar panels are losing efficiency?

Monitor your energy output regularly. If production drops significantly without weather or shading changes, it may indicate degradation or technical issues.

4. Do portable solar panels last as long as rooftop panels?

Portable panels generally have shorter lifespans (10–15 years) due to frequent movement, folding, and exposure, but high-end models with ETFE coating can last longer.

5. What shortens a solar panel’s lifespan?

Extreme weather, poor installation, lack of maintenance, and mechanical stress can reduce performance over time.

6. Can solar panels be recycled?

Yes. Many recycling programs reclaim valuable materials such as silicon, glass, and aluminum, reducing environmental impact.

7. Is investing in solar panels still worth it?

Absolutely. The long lifespan, minimal maintenance, and potential for energy independence make solar panels one of the best long-term energy investments.