As hurricane winds howled through Louisiana, Sarah watched her phone battery dip to 3% while emergency alerts flashed across the screen—until she unfolded a portable solar panel on her rain-slicked windowsill. Within minutes, the dying device pulsed back to life, connecting her to rescue services. This simple act of harnessing sunlight during catastrophe underscores why portable solar panels have evolved from camping luxuries to essential lifelines. Whether weathering blackouts or exploring remote wilderness, understanding how to efficiently charge batteries with sunlight transforms uncertainty into empowerment.

The magic lies not just in capturing photons, but in navigating voltage curves, alignment angles, and charge profiles that determine whether your devices survive emergencies or go dark. Unlike wall outlets that deliver predictable power, solar charging dances with cloud cover, temperature swings, and the Earth’s rotation—variables demanding both technical knowledge and practical finesse. Let’s illuminate the path from sunlight to stored energy.

Core Principles of Solar Charging Physics

Portable solar panels convert sunlight into electricity through photovoltaic cells, typically monocrystalline silicon for their 20-25% efficiency. When photons strike these cells, they dislodge electrons, creating direct current (DC) electricity. This raw energy flows to your battery via a charge controller—the indispensable brain preventing overcharging. For lead-acid batteries, controllers use PWM (Pulse Width Modulation), rapidly switching current on/off to maintain safe voltage. Lithium batteries like LiFePO4 require MPPT (Maximum Power Point Tracking) controllers, which dynamically adjust electrical resistance to harvest up to 30% more energy by matching the panel's optimal voltage-current curve. Consider a 100W panel: under ideal noon sun, it might produce 21V and 4.8A (21V × 4.8A = 100.8W). An MPPT controller can transform excess voltage into additional amperage—converting 21V at 4.8A to 14.4V (standard battery voltage) at 7A, thus delivering more power than PWM's direct connection. Temperature dramatically affects output; panels lose 0.3-0.5% efficiency per °F above 77°F, while cold boosts voltage but may thicken battery electrolytes. Understanding these interactions prevents frustrating "why isn't it charging?" scenarios during critical moments.

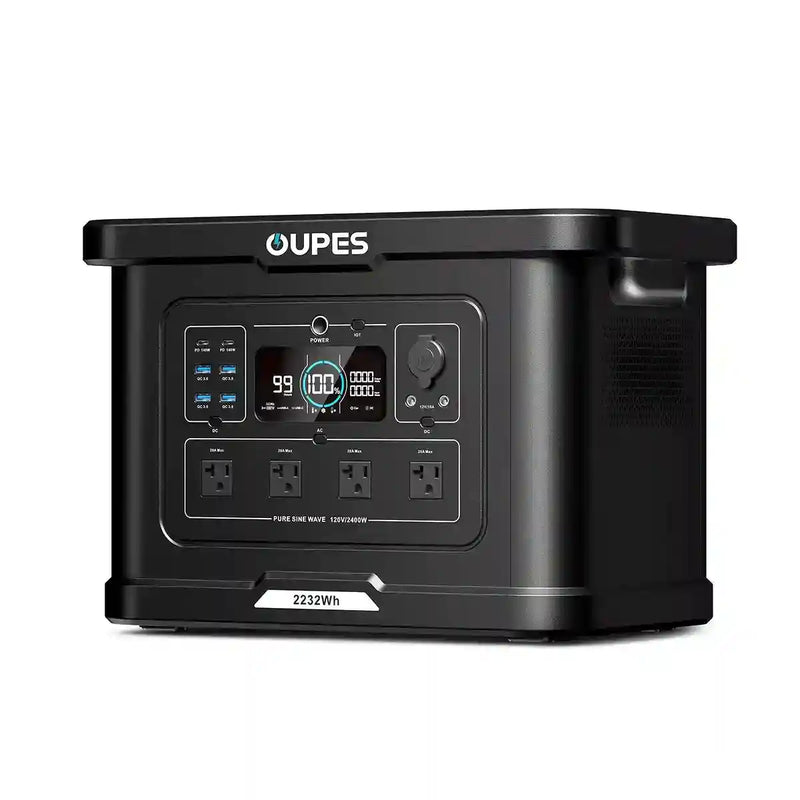

Battery chemistry dictates charging strategies. Flooded lead-acid batteries need periodic equalization charges at 15-16V to prevent sulfation, whereas sealed AGM batteries risk venting if exceeded 14.6V. Lithium batteries demand precise voltage staging: bulk charging (constant current) until reaching 80% capacity, then absorption (constant voltage) for the remaining 20%. Solar generators like OUPES integrate these protocols automatically, but standalone systems require controller configuration. Always match panel voltage to battery requirements; a 12V battery needs 18-22V panel input to overcome losses, while 24V systems pair with 36V panels. Neglecting voltage compatibility risks incomplete charges or battery damage—especially crucial when powering medical devices during extended outages where reliability isn’t optional.

Selecting and Positioning Your Solar Array

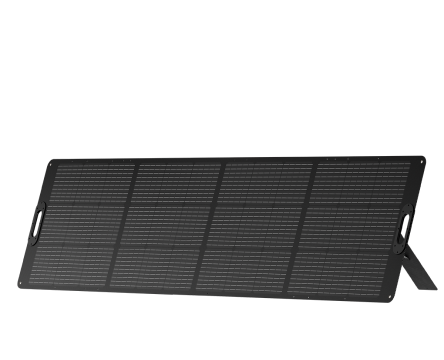

Panel selection hinges on three factors: efficiency, portability, and environmental durability. Monocrystalline panels outperform polycrystalline in low light, making them ideal for overcast regions. For backpacking, 20-40W foldable panels weighing under 4lbs suffice for phones and headlamps. Emergency home backup requires rigid 100-200W panels with aluminum frames—like OUPES’ 200W suitcase models with kickstands—capable of charging power stations for refrigerators or CPAP machines. Water resistance matters profoundly; IP65-rated panels withstand rain and snow, while non-rated units fail when humidity seeps into junction boxes. Connector types are equally critical: MC4 connectors provide secure, waterproof links, whereas alligator clips introduce resistance and corrosion. Always carry adapter kits for USB-C, DC5521, and Anderson plugs to interface with diverse devices.

Positioning transforms adequate charging into optimal harvesting. The golden rule: align panels perpendicular to the sun’s rays. At solar noon, tilt panels equal to your latitude (e.g., 34° in Los Angeles). In morning/evening, reduce tilt by 15°. Use compass apps for true azimuth alignment—180° south in Northern Hemisphere. Dynamic tracking boosts yield 25%: adjust angles every 2 hours or use auto-tracking mounts. Avoid shadows obsessively; a 10% shaded cell can slash output 50%. During winter, place panels on reflective surfaces like snow or light-colored tarps to amplify light. For vehicles, magnetic mounts secure panels to roofs while driving, but park facing equatorially. In campsites, hang panels vertically on tents to capture low-angle winter sun. Carry telescoping poles for elevation above ground heat, which reduces efficiency. Documented testing shows proper alignment in December generates triple the energy of flat-positioned panels.

Step-by-Step Charging Sequence and Monitoring

Begin with pre-charge safety checks: inspect panels for cracks, clean surfaces with microfiber cloths, and verify cable integrity. Connect components in sequence: panels → charge controller → battery. Never connect panels directly to batteries—voltage spikes can destroy electronics. For OUPES solar generators, integrated controllers handle regulation; simply plug panels into the station’s DC input. Startup sequence matters: on cloudy days, connect panels first to build voltage, then attach batteries. In full sun, reverse the order to prevent controller overload. Monitoring real-time data prevents failures; quality controllers display voltage, amperage, and watt-hours accumulated. Expect a 100W panel to deliver 300-500Wh daily depending on location—enough to recharge a 40,000mAh power station. Track performance: if output drops below 50% of panel rating (e.g., <50W on 100W panel), troubleshoot connections or shading.

Multi-panel configurations demand series/parallel decisions. Series connections (positive to negative) increase voltage: two 20V panels become 40V, minimizing amperage loss over long cable runs. Parallel connections (positive to positive) increase amperage: two 5A panels produce 10A, ideal for short distances. For 24V battery systems, choose series; 12V systems use parallel. When mixing panels, match voltages within 0.5V to prevent reverse currents. During partial shading, parallel wiring outperforms series—one shaded panel won’t cripple the entire array. Always use identical cable lengths to balance resistance. For expansion, OUPES’ systems allow linking extra panels via parallel connectors, scaling to 400W for rapid power station recharging. Log daily watt-hours using Bluetooth apps; consistent declines indicate panel degradation or battery health issues requiring intervention.

Environmental Optimization and Troubleshooting

Weather adaptation separates novices from experts. In full sun, elevate panels 6" above surfaces to prevent efficiency-robbing heat buildup—output drops 1% per 4°F above 77°F. Use cooling techniques: place panels over grass (not asphalt) or mist lightly with water in extreme heat. Under clouds, switch to parallel wiring to capture diffuse light more effectively. Rain demands vigilance: seal connectors with dielectric grease, and angle panels at 60° to encourage water runoff while still capturing 70% of normal light. Snow requires gentle brushing with soft brooms—never hot water, which cracks glass. Below freezing, lithium batteries charge slower; insulate them in thermal bags while allowing ventilation.

Troubleshoot systematically. Zero output? Test panel voltage with a multimeter—should read 18-22V for 12V systems under sun. If adequate, inspect fuses and connectors for corrosion. Low amperage? Check for micro-shadows from branches or debris. Partial shading triggers bypass diodes to shut down sections—reposition immediately. Intermittent charging often stems from loose MC4 connectors; tighten and weatherproof. If controllers display error codes, reset by disconnecting all components for 10 minutes. Battery not reaching full capacity? Verify absorption stage duration; lithium batteries need 2-3 hours at constant voltage after bulk charging. For deep-cycle batteries, perform monthly equalization charges at higher voltages to dissolve sulfate crystals. Document performance benchmarks: a 100W panel should produce 5-8A at noon—persistent shortfalls signal panel degradation or controller failure.

Safety Protocols and Long-Term Maintenance

Electrical safety prevents catastrophic failures. Never exceed controller amperage ratings—a 10A controller paired with 200W of panels at 12V (16.6A) risks meltdown. Use 10-12AWG cables for runs over 15ft to prevent voltage drop and overheating. Install 15A fuses between panels and controllers, and match fuse ratings to wire capacity. Avoid daisy-chaining panels when wet; moisture enables arcing between connectors. When charging indoors, route cables through cracked windows—never pinch cords in frames. Lithium batteries require strict thermal management; never charge below 32°F or above 113°F to prevent plating or thermal runaway. Store power stations at 50% charge in 50-77°F environments to maximize lifespan.

Maintenance preserves peak efficiency. Clean panels biweekly with distilled water and isopropyl alcohol—dust reduces output up to 25%. Inspect cables monthly for rodent damage or brittleness. Annually test open-circuit voltage: a 20% drop indicates panel replacement. For controllers, update firmware via USB to improve MPPT algorithms. Store foldable panels unfolded in dark, dry places to prevent delamination. Battery maintenance varies: lithium needs monthly full discharges to calibrate monitors, while lead-acid requires quarterly terminal cleaning with baking soda paste. Label cables with voltage/amperage ratings to prevent mismatches during emergencies. Record performance logs; a 5% annual output decline is normal, but steeper drops warrant professional diagnostics. These rituals ensure your solar kit delivers reliably when storms knock out grid power for weeks.

Mastering portable solar charging transforms sunlight from abstract energy into tangible security. By comprehending the interplay between photovoltaic physics, battery chemistry, and environmental variables, you build resilience against both daily inconveniences and large-scale disasters. The techniques detailed here—from optimal panel tilting to lithium charging protocols—convert theoretical knowledge into uninterrupted power for communications, medical devices, and essential appliances.

As climate volatility increases, the ability to harness solar energy independently becomes not just a skill, but a vital layer of personal infrastructure. Portable panels paired with capable solar generators form a decentralized power network that operates when centralized grids fail. Embrace these principles, and you’ll never see sunlight merely as illumination—but as liberation from vulnerability.