That smartphone dying before lunch, the electric vehicle losing range year after year, the power drill that just doesn't hold a charge like it used to—all point toward the inevitable reality of lithium-ion (Li-ion) battery degradation. As the powerhouse behind our modern portable and electric world, understanding how these ubiquitous energy sources age is crucial. While remarkably efficient, Li-ion batteries aren't eternal; they operate within a delicate chemical balance that shifts imperceptibly with every charge, every discharge, and even while sitting idle. From the microscopic breakdown of electrodes to the cumulative stress of temperature extremes, multiple forces conspire to reduce their capacity and performance over time. But how long should they realistically last? Is your battery failing prematurely, or is it simply following its natural lifespan? Understanding these internal processes and the key factors that accelerate or mitigate decay—including how you charge, discharge, and store your devices—empowers you to make informed choices, maximize your battery's useful life, reduce replacement costs, and minimize environmental impact.

The Chemistry Behind Lithium-Ion Battery Degradation

At the heart of every lithium-ion battery's finite lifespan lie intricate chemical and physical changes occurring within its cells. Unlike mechanical wear that we can see or hear, battery degradation happens at the atomic level. During normal operation, lithium ions shuttle back and forth between the positive electrode (cathode, often made of materials like lithium cobalt oxide, NMC, or LFP) and the negative electrode (anode, typically graphite). This seemingly simple process is fraught with complexities that cause irreversible capacity loss over time. One primary mechanism involves the continuous formation and thickening of the Solid Electrolyte Interphase (SEI). Initially, this thin layer forms on the anode surface during the first few charge cycles, stabilizing the interface. However, over prolonged cycling, this layer keeps growing, consuming active lithium ions and electrolyte components. This irreversible consumption means fewer lithium ions are available for energy storage and release, directly reducing the battery's maximum capacity. Furthermore, a thicker SEI layer increases internal resistance, leading to voltage drops under load and decreased power output, making your device feel sluggish even when 'fully' charged.

Other degradation pathways exist simultaneously. The constant expansion and contraction of electrode materials during lithium insertion (charging) and extraction (discharging) generate mechanical stress. Over thousands of cycles, this stress can cause microscopic cracks in the electrodes, fragmenting particles and destroying vital electrical connections within the electrode structure. These cracks isolate active material, rendering it useless for storing lithium ions. Degradation also affects the cathode. Materials like nickel or manganese can slowly dissolve into the electrolyte, especially at high operating temperatures or voltages, diminishing the cathode's ability to intercalate lithium ions effectively. The electrolyte itself isn't inert; it decomposes over time, generating gas (potentially leading to swelling) and further depleting the available lithium and electrolyte volume. Even the binder materials holding the active electrode particles together can deteriorate, contributing to electrode delamination and electrical isolation. These interconnected processes occur continuously, gradually diminishing both the energy the battery can store (capacity fade) and the power it can deliver (power fade), defining the ultimate lifespan.

Calendar Aging vs. Cycle Aging: Twin Pillars of Lifespan

The journey toward a Li-ion battery's end-of-life is traveled via two distinct, yet often overlapping, pathways: calendar aging and cycle aging. Understanding this duality is essential to managing expectations and optimizing battery health. Calendar aging refers to the unavoidable, passive degradation that occurs simply with the passage of time, regardless of whether the battery is being used. Chemical reactions within the cell, particularly those involving the electrolyte decomposition and SEI layer growth, proceed slowly even when the battery is sitting on a shelf turned off. Think of it like metal rusting slowly in humid air. Several factors accelerate calendar aging exponentially. Temperature is paramount: the Arrhenius equation dictates that chemical reaction rates approximately double for every 10°C (18°F) increase. Storing a lithium-ion battery at 40°C (104°F) causes degradation roughly four times faster than storing it at 20°C (68°F). Equally critical is the State of Charge (SoC) during storage. High SoC (especially above 80% or near 100%) creates significant chemical stress within the cell, promoting electrolyte decomposition and parasitic reactions at the electrodes.

Cycle aging, conversely, results directly from the active use of the battery – discharging and recharging it. Each complete charge-discharge cycle inflicts cumulative micro-damage. Factors influencing how damaging each cycle is include the Depth of Discharge (DoD): shallow discharges (e.g., from 80% to 60%) cause significantly less wear per cycle than deep discharges (e.g., from 100% to 20%). Cycling a battery only partially significantly extends its cycle life compared to frequent full discharges. Charging speed is another major factor. Rapid charging forces lithium ions into the anode graphite structure much faster, increasing the likelihood of lithium plating (metallic lithium deposits forming instead of cleanly intercalating), which permanently consumes lithium and can create dangerous dendrites. High charging rates also generate more internal heat, further accelerating degradation processes. Similarly, discharging at very high currents (heavy loads) causes voltage sag and heat buildup, stressing the battery. Both extremes of operation – operating at very low voltage (deep discharge) and very high voltage (fully charged) – impose additional chemical stresses. Therefore, a battery's total lifespan is a complex interplay between how many cycles it undergoes and how quickly it ages chemically while idle, influenced heavily by environmental and usage conditions.

Practical Strategies for Maximizing Battery Longevity

While degradation is inevitable, smart usage habits can significantly slow the process, maximizing both the years of service and the functional capacity retained within those years. Temperature management is paramount. Avoid exposing devices to prolonged heat. Keep phones and laptops out of direct sunlight (like car dashboards), never charge devices under pillows or heavy covers where heat can build up, and store spare batteries or devices in cool locations (aiming for 10-25°C or 50-77°F is ideal). Many electric vehicles actively manage battery temperature using liquid cooling or heating systems; allowing these systems to operate effectively by parking in shade or garages when possible contributes to longevity. Charging habits play an equally vital role. Embrace partial charging cycles. Instead of consistently draining to 0% and charging to 100%, aim to keep batteries mostly between 20% and 80% charge. Deep discharges are particularly stressful, and storing batteries at 100% charge creates ongoing chemical stress for calendar aging. If storing a device or battery for several weeks or months, charge it to approximately 50% first; this minimizes chemical stress during idle periods.

Modern devices often include software-based longevity features. Activate 'Optimized Battery Charging' on iPhones or 'Adaptive Charging' on Android devices. These features learn your daily charging patterns and delay fully charging to 100% until shortly before you typically unplug, reducing the time spent at high voltage. Utilize manufacturer-provided power profiles where available; electric vehicles often have "Daily Drive" and "Trip" charging limits, encouraging users to set the daily limit to 70-80% unless the full range is needed immediately. Avoid the constant "bump charging" habit – plugging in for short bursts repeatedly to keep the device near 100%. This keeps the battery constantly at high voltage and unnecessarily increases cycle count. When charging is required, use moderate speeds when possible; while occasional fast charging is convenient, relying on it constantly accelerates degradation. Wireless charging, while convenient, typically generates more heat than well-designed wired chargers; use it judiciously, avoiding overnight charging on a wireless pad which combines high SoC, sustained heat, and lengthy charging periods.

Typical Lifespan Expectations Across Different Devices

The practical lifespan of a Li-ion battery—meaning the duration until its capacity diminishes to a point where it no longer adequately serves the device's intended purpose—varies significantly depending on the application, inherent design robustness, and typical usage patterns. Smartphones represent one of the most demanding environments. Battery size is constrained by device thinness, yet the power demands from large bright screens and powerful processors are substantial. Coupled with frequent daily charging (often including overnight or all-day charging at desks), exposure to heat in pockets, and expectations of compact size leading to minimal protection against deep discharges, smartphone batteries experience significant stress. Consequently, consumers might notice decreased endurance within 18-24 months, reaching the common threshold of 80% remaining capacity often in 2-3 years. Manufacturers usually design for about 500-800 full equivalent cycles before reaching this point, though aggressive charging habits and ambient heat can drastically shorten this.

Laptop batteries benefit from a larger physical footprint, allowing for bigger cells and sometimes less aggressive power management versus peak smartphone demands. The thermal environment can also be somewhat less extreme than phones constantly held or pocketed. However, users often leave laptops plugged in constantly, keeping the battery at 100% charge under elevated internal temperatures—a perfect storm for accelerated calendar aging. Conversely, laptops used exclusively on battery might undergo deeper discharges. As a result, useful laptop battery life typically ranges from 3 to 5 years or 300-500 cycles, heavily influenced by usage patterns and thermal conditions during operation and charging. Electric Vehicle (EV) batteries are engineered to prioritize longevity above nearly all else. They feature robust thermal management systems (liquid cooling/heating), sophisticated Battery Management Systems (BMS), and large capacity buffers that prevent operation at voltage extremes. The battery also constitutes a huge portion of the vehicle's cost.

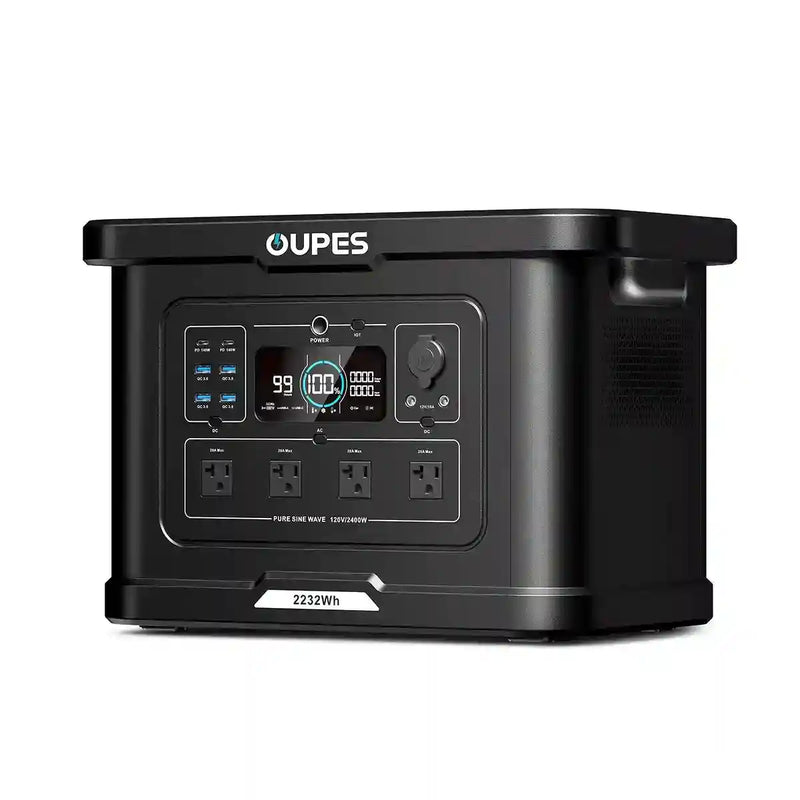

Therefore, automakers design these packs for much longer lives. Most warranties cover battery capacity retention for 8 years or 100,000 miles (sometimes longer), often guaranteeing at least 70-75% remaining capacity. In reality, with moderate usage and avoidance of constant deep discharges and ultra-fast charging, many EV batteries retain well over 80% capacity after 150,000-200,000 miles. Stationary storage batteries (like home Powerwalls or grid systems) experience gentler cycling patterns and optimized temperature control, enabling extremely long predicted lifespans—10 to 15 years or more—as they aren't subjected to the physical shocks, vibration, and wide temperature fluctuations of mobile applications.

Recycling and End-of-Life Management Considerations

As lithium-ion batteries reach their end of useful service life—defined not by sudden failure but by their diminished capacity and performance becoming insufficient for the intended application—responsible disposal becomes critical. Discarding them in regular household trash creates environmental hazards and squanders valuable materials. When batteries degrade and swell, the internal cell structure becomes compromised, increasing the risk of thermal runaway—an uncontrolled self-heating reaction leading to fire and release of toxic gasses—particularly if damaged during transport or compaction in waste trucks. The electrolytes used are organic solvents, often flammable and toxic. Furthermore, cathode materials contain metals like cobalt, nickel, manganese, and lithium itself, which are finite resources often mined under challenging conditions.

Recycling offers a crucial solution, recovering significant portions of these valuable materials and reducing the need for new mining and the associated environmental and social costs. Specialized facilities use complex processes, typically involving pyrometallurgy (smelting at high temperatures) or hydrometallurgy (chemical leaching), to extract these metals. While recovery rates are improving, they are still not perfect (e.g., recovering lithium efficiently remains challenging in some processes). The recycling infrastructure is rapidly expanding, driven by increasing volumes from EVs and portable electronics and stricter government regulations promoting producer responsibility. Consumers have a vital role: never dispose of Li-ion batteries in general waste. Instead, locate authorized collection points: electronics retailers, municipal hazardous waste facilities, specialized battery recyclers, or programs operated by manufacturers like Apple or automakers. Proper recycling mitigates fire risks during waste handling, prevents soil and water contamination, and conserves critical raw materials essential for building the next generation of batteries needed for a sustainable energy future.

Lithium-ion battery lifespan, while inherently finite, is deeply influenced by complex chemical processes and user practices. The interplay between calendar aging—degradation simply with the passage of time, accelerated by high temperatures and states of charge—and cycle aging—wear incurred through charging and discharging operations, aggravated by deep discharges, high speeds, and extremes of operation—determines the trajectory of capacity fade and power fade. While degradation mechanisms like SEI layer growth, electrolyte decomposition, and electrode fracturing operate at the atomic level, everyday choices on charging habits, environmental protection, and usage patterns significantly impact the speed of this decline. Understanding that different applications have varying lifespan expectations—2-3 years for demanding smartphones, 3-5 years for laptops, and potentially 10-15+ years for well-managed EVs and stationary storage—helps set realistic expectations.

Adopting simple practices, primarily avoiding extreme temperatures and high states of charge for prolonged periods, charging slowly and partially when possible, and leveraging device software features designed to preserve longevity, can significantly extend usable battery life. Finally, recognizing that even batteries past their prime contain valuable and hazardous materials underscores the critical importance of responsible disposal through certified recycling channels. Mastering these principles empowers users to maximize their device performance, minimize replacement frequency and associated costs, reduce electronic waste, and contribute to the sustainable lifecycle management of these indispensable energy storage components.